Highlights

Jan 28, 2009

Center for Emergent Materials (2014)

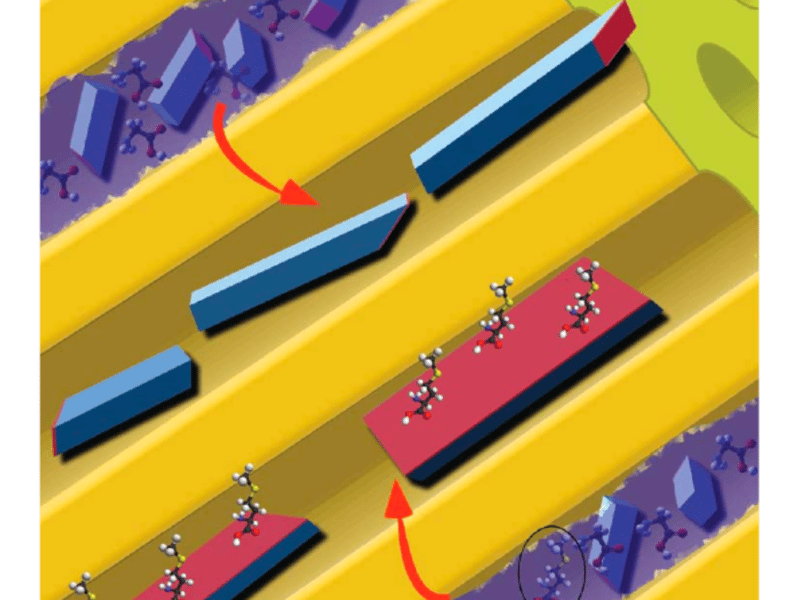

Toward Site-Specific Stamping of Graphene

D. Li, W. Windl and N.P. Padture, The Ohio State University

A physical hypothesis based on theory and ab initio modeling for the stamping of graphene and few layers graphene (FLG) on silica is presented, and the feasibility of site-specific stamping of FLG patterns is demonstrated experimentally (figure below shows 10-layer FLG pattern stamped on silica). The site-specific nature of the patterned stamps over large areas could enable high-throughput fabrication of future graphene-based integrated devices.

Jan 21, 2009

UMN Materials Research Science and Engineering Center (2014)

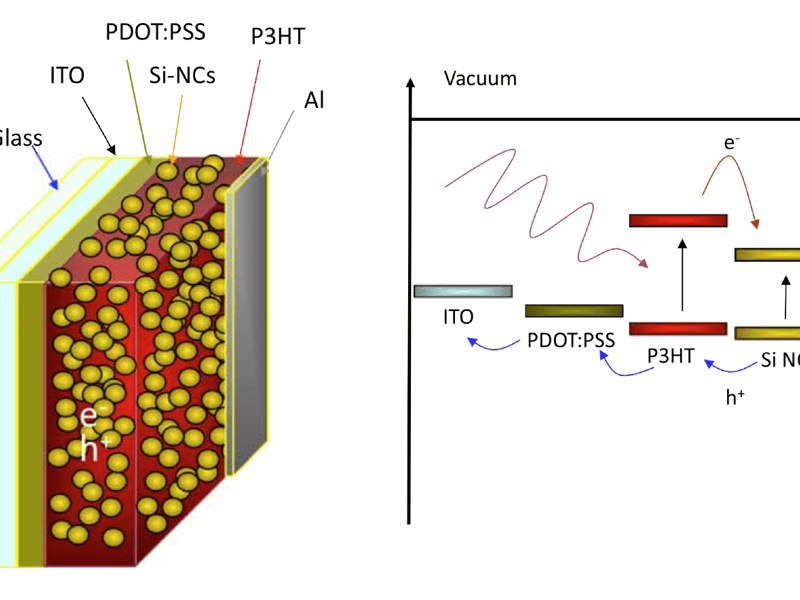

Hybrid Silicon Nanocrystal-Polymer Solar Cells

Uwe Kortshagen

Mr. Chin-Yi Liu, a graduate student working in Professor Kortshagen’s group, demonstrated the first hybrid solar cell based on silicon nanocrystals and a conductive polymer, poly-3(hexylthiophene) (P3HT).

Jan 21, 2009

UMN Materials Research Science and Engineering Center (2014)

Manipulating Crystal Orientation in Nanopores

Marc Hillmyer

The UMN MRSEC has demonstrated the control of nanocrystal orientation within nanoporous polymer monoliths prepared from ABC triblock terpolymers containing a robust A block (polystyrene), a hydrophilic B block [poly(dimethylacrylamide)], and an etchable C block (polylactide) developed in the IRG.

Jan 21, 2009

UMN Materials Research Science and Engineering Center (2014)

Magnetics Day - Magnetism in Technology

Paul Crowell, Chris Leighton, Dan Dahlberg

MRSEC faculty members Paul Crowell, Chris Leighton, and Dan Dahlberg and their students guided 25 high school students through an exploration of magnetism and its applications to technology as part of the Institute of Technology Center for Education Programs (ITCEP) Exploring Careers in Science & Engineering summer camp. The day of activities included hands-on demos, a lunch with recent graduates working in industry, and an afternoon spent building motors, magnetic levitators, generators, and radios.

Jan 8, 2009

Princeton Center for Complex Materials (2014)

Defect Density Limits Orientational Order in Shear-Aligned Block Copolymer Films

Andy Marencic, Mingshaw Wu, Paul Chaikin (NYU), and Rick Register

Self-assembling block copolymers provide a simple, efficient, and rapid way to generate nanoscale patterns over macroscopic areas:Â’ for example, an array of 20 nm dots covering a 100 mm silicon wafer.Â’ These dots can be "lined up" by applying shear to the block copolymer film [1], but the order is not perfect:Â’ dislocations (lines of dots that abruptly start or end) remain in the film.Â’ In a recent study [2], PCCM researchers have shown that the quality of orientational order of the dots depends only on the density of these dislocations; in the limit that dislocations are

Dec 19, 2008

Northwestern Materials Research Science and Engineering Center

Multiscale Patterning of Plasmonic Metamaterials

Joel Henzie, Min Hyung Lee, and Teri W. Odom Northwestern University Materials Research Science & Engineering Center, DMR-0520513

Surface plasmons - collective oscillations of free charges - on metal surfaces have resulted in demonstrations of enhanced optical transmission, collimation of light through a subwavelength aperture, negative permeability and refraction at visible wavelengths, and second-harmonic generation. The structures that display these plasmonic phenomena typically consist of ordered arrays of particles or holes with sizes of the order of 100 nm.

Dec 19, 2008

Northwestern Materials Research Science and Engineering Center

Atomic Force Photovoltaic Microscopy

B. J. Leever, M. F. Durstock, M. D. Irwin, A. W. Hains, T. J. Marks, L. S. C. Pingree, and M. C. Hersam Northwestern University Materials Research Science & Engineering Center DMR-0520513

Organic photovoltaic devices (OPVs) hold promise for a variety of applications requiring alternative energy generation. Through a collaboration betweenÂ’ Northwestern University MRSEC IRG 4 and Wright Patterson Air Force Base, a new strategy for characterizing the electrical and optical performance of operating OPVs has recently been developed. Atomic force photovoltaic microscopy allows the photocurrent response in OPVs and other optoelectronically-active materials and devices to be spatially mapped down to the nanometer length scale.

Dec 19, 2008

Northwestern Materials Research Science and Engineering Center

The Art of Science and the Science of Art

Katherine T. Faber Northwestern University Materials Research Science & Engineering Center, DMR-0520513

A partnership between the NU-MRSEC and the Art Institute of Chicago provides fertile ground for curriculum development. Lisa Backus, a high school chemistry teacher and participant in the Center's 2006Â’ Research Experience for Teachers (RET) program was inspired by her summer research project working on conservation science problems of Ancient Chinese jades and Winslow Homer watercolors. The result is an art-based high school chemistry module that introduces students to the properties of light, the atom, and organic compound pigments.

Showing 1191 to 1200 of 1394