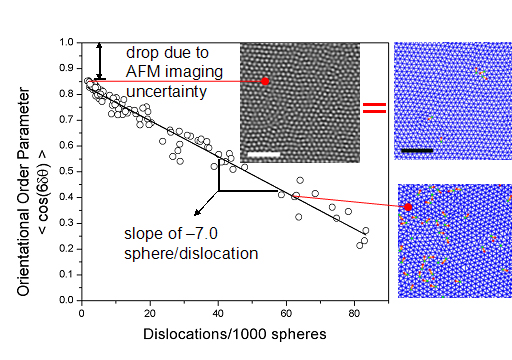

Self-assembling block copolymers provide a simple, efficient, and rapid way to generate nanoscale patterns over macroscopic areas:Â’ for example, an array of 20 nm dots covering a 100 mm silicon wafer.Â’ These dots can be "lined up" by applying shear to the block copolymer film [1], but the order is not perfect:Â’ dislocations (lines of dots that abruptly start or end) remain in the film.Â’ In a recent study [2], PCCM researchers have shown that the quality of orientational order of the dots depends only on the density of these dislocations; in the limit that dislocations are absent, the order is as perfect as can be measured with an atomic force microscope (AFM).Â’ The quality of order decreases linearly with the number of dislocations; a simple model adapted from solid mechanics predicts the magnitude of the contribution made by each dislocation.

Main figure: Orientation quality vs. dislocation density in shear-aligned sphere-forming block copolymer thin films, showing a simple linear dependence, indicating each defect makes an independent debit contribution to the order. Order parameter at zero dislocation density (=0.85) results from imperfect location of the spheres (dots) by AFM. Insets (clockwise from top): AFM image (scale bar = 200 nm) showing array of spheres with a low dislocation density; Delaunay triangulation of the same image, showing dislocations as pairs of green and red dots connected by orange stripes; Delaunay triangulation of an image with high dislocation density.