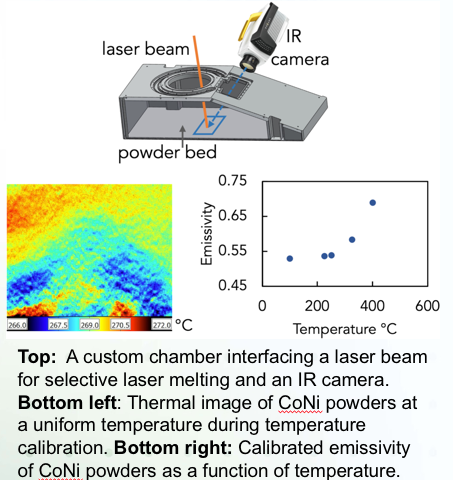

Intellectual merit: Temperature has been shown to be a critical factor impacting additive manufacturing (AM). During selective laser melting (SLM), the heat transfer and fluid flow affect grain growth and the microstructure of the printed material. Previous efforts have mostly relied on tuning parameters such as laser power and scan rate, but a more detailed understanding of temperature effects in AM is still lacking. In this Seed, we will probe and understand how dynamic and localized heating and cooling affect the microstructure of additive manufactured (AM) materials by operando temperature mapping and machine learning. The insight gained will allow us to optimize AM processes by tuning thermal interfacial resistance.

Broader Impacts: Insights from this work will aid the optimization of metal melting protocols for AM, and guide the search for new AM materials with improved

microstructures and strength. It will also lead to real time diagnosis of AM processes.