Like liquids, solids can flow under applied shear stresses. In crystalline solids, figuring out vulnerable regions where the material will break under stress is well-established—they are typically controlled by a population of defects in the crystal structure known as dislocations. In disordered solids, however, defects are everywhere, making the task of identifying such vulnerable spots much more daunting.

When a disordered solid is placed under mechanical load, it can fail via localized rearrangements of particles. These rearrangements are what allow the solid to flow. We showed that there is a link between the nature of vibrations in disordered packings and mechanical failure. We studied the vibrations of thermosensitive colloidal particles in a dense packing before it was placed under compression, identifying a population of soft spots. We then showed that these localized regions are indeed vulnerable to rearrangement. Thus, we are now able to identify the vulnerable regions in a dense, disordered packing before it fails under a load. We are now examining the ways in which these results apply to disordered atomic packings.

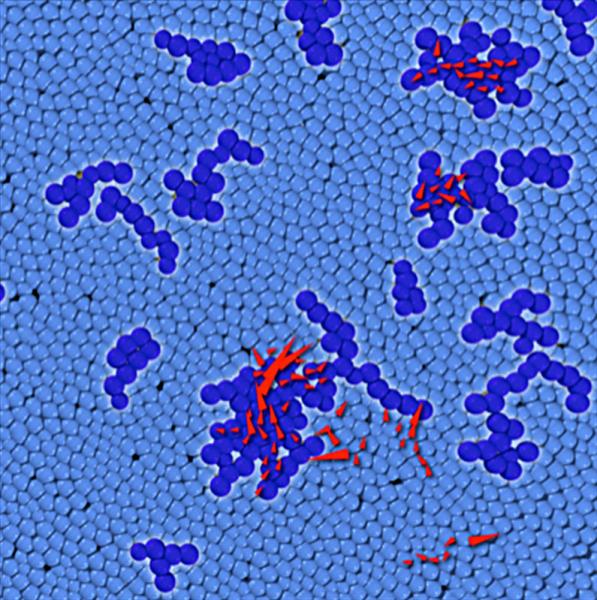

In a dense disordered packing, the particles labeled in dark blue belong to soft spots that have a propensity to fail via particle rearrangements. The red arrows mark particles that actually rearrange when the system is placed under a mechanical load. This image shows that rearrangements tend to occur at soft spots.