Highlights

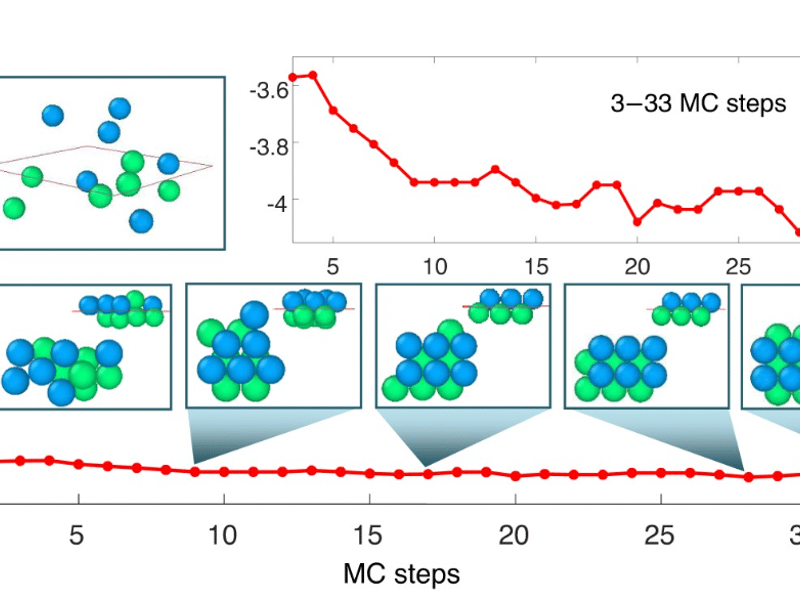

Discovery of bilayer nanoparticle (NP) superlattices using global Monte Carlo optimization

Yilong Zhou, Gaurav Arya, Duke University

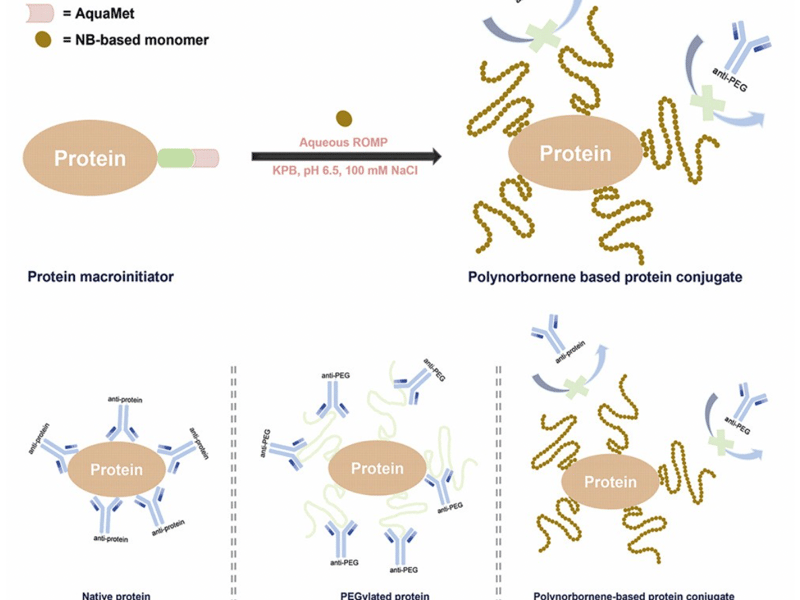

Where Materials Begin and Society BenefitsFirst Demonstration of Controlled Grafting-from ROMP Bioconjugates

Derek Church, Elizabathe Davis, Adam Caparco, Nicole Steinmetz, Jon Pokorski, UC San Diego

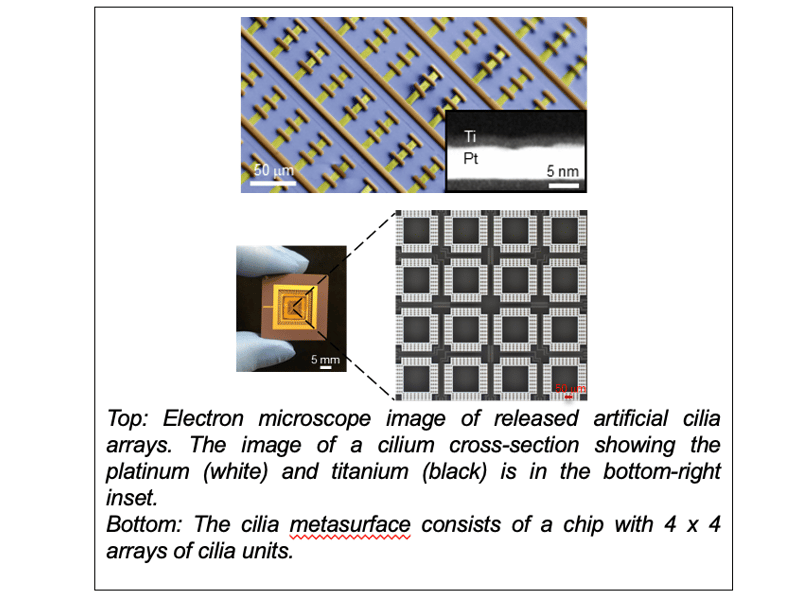

Breakthrough in Artificial Cilia Materials Opens the Door to Programmable Microfluidic Manipulation

W. Wang, Q. Liu, I. Tanasijevic, M. F. Reynolds, M. Z. Miskin, M. C. Cao, D. A. Muller, A. C. Molnar, E. Lauga, P. L. McEuen, and I. Cohen (Cornell University) A. J. Cortese (OWiC, Inc.)

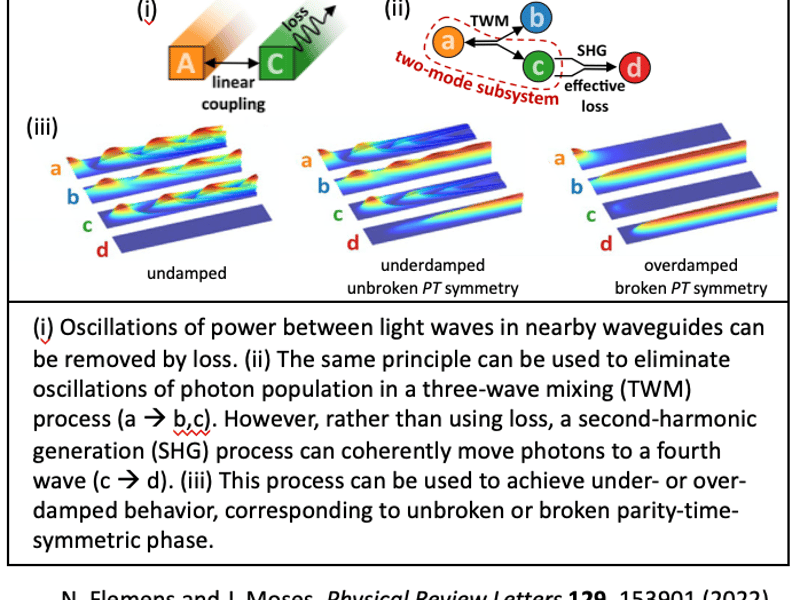

Lossless Removal of Unwanted Waves from Photonic Devices

N. Flemens and J. Moses, Cornell University

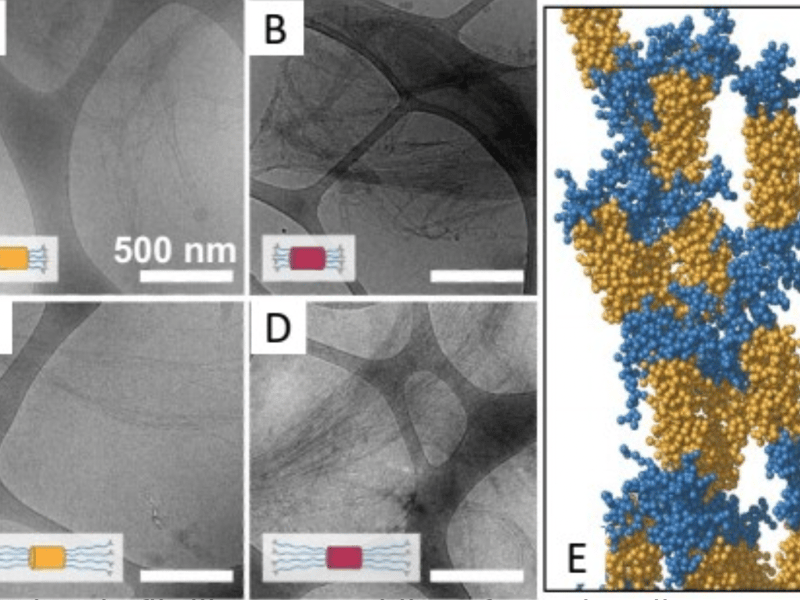

Genetic Fusion of Thermoresponsive Polypeptides Mediates 1-D Assembly of Coiled Coil Bundlemers

Sai Patkar*, Yao Tang*, Darrin Pochan*, Kristi Kiick*, *Materials Science and Engineering, Biomedical EngineeringTianren Zhang*, Jeffrey Saven, Chemistry, University of Pennsylvania

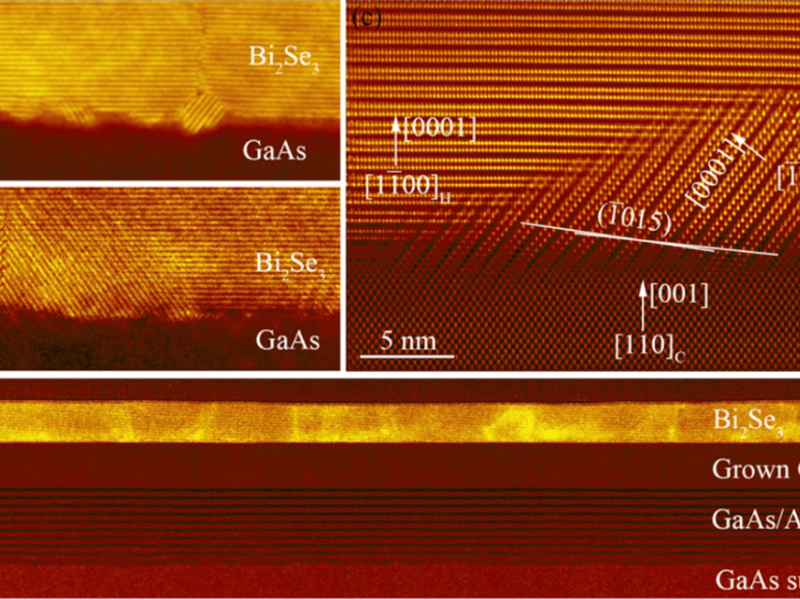

Bi2Se3 Growth on (001) GaAs Substrates for Terahertz Integrated Systems

Y. Liu1, W. Acuna1, H. Zhang2, D. Q. Ho1, R. Hu1, Z. Wang1, A. Janotti1, G. Bryant2, A. V.Davydov2, J. M. O. Zide1, and S. Law1 - (1 University of Delaware (UD); 2 NIST)

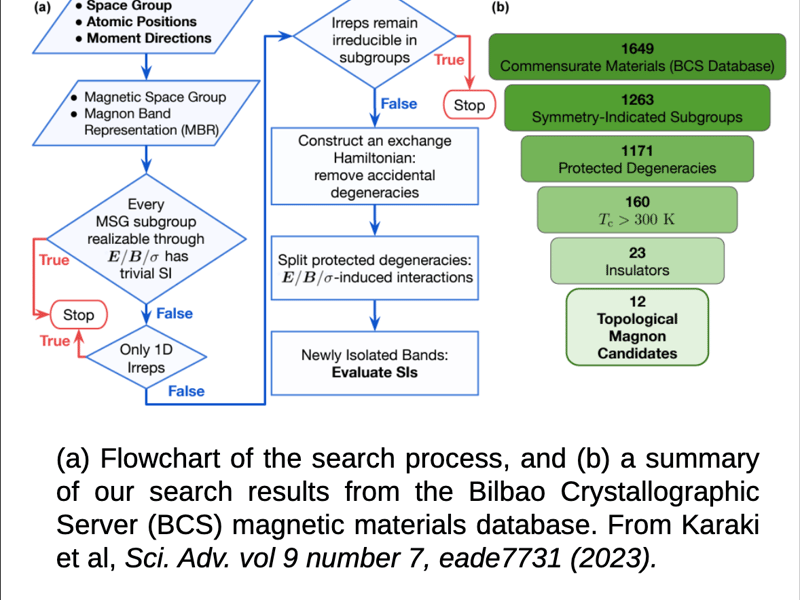

An efficient material search for room-temperature topological magnons

Lu (OSU Physics), Goldberger (OSU Chemistry), Doan-Nguyen(OSU MSE)

Strengthening Networks: Connecting MRSEC and PREM Students with Academic and Industry Representatives

Richard (OSU), Pak (UCSB), Nawwar (OSU), Endsley (UCSB), Tak (UCSB)

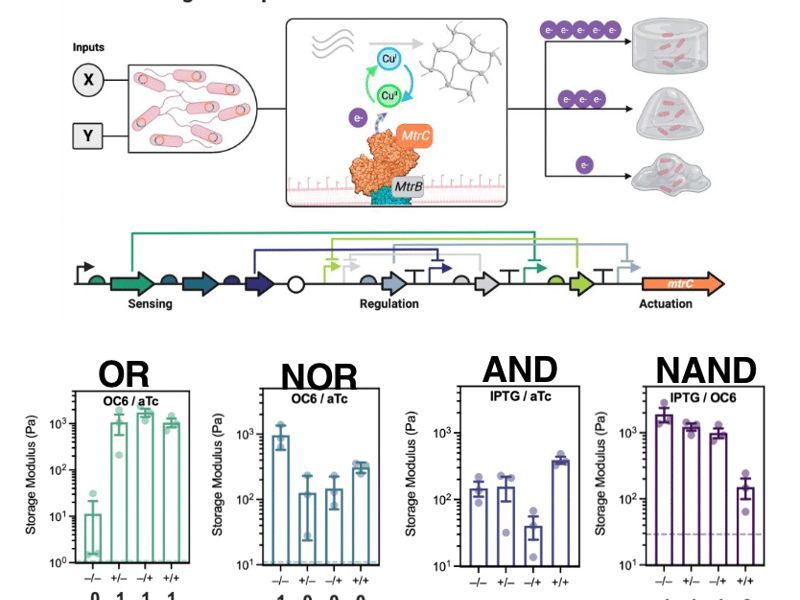

Hydrogel Crosslinking Regulated using Genetic Logic

B.K. Keitz, A.M. Rosales: UT Austin

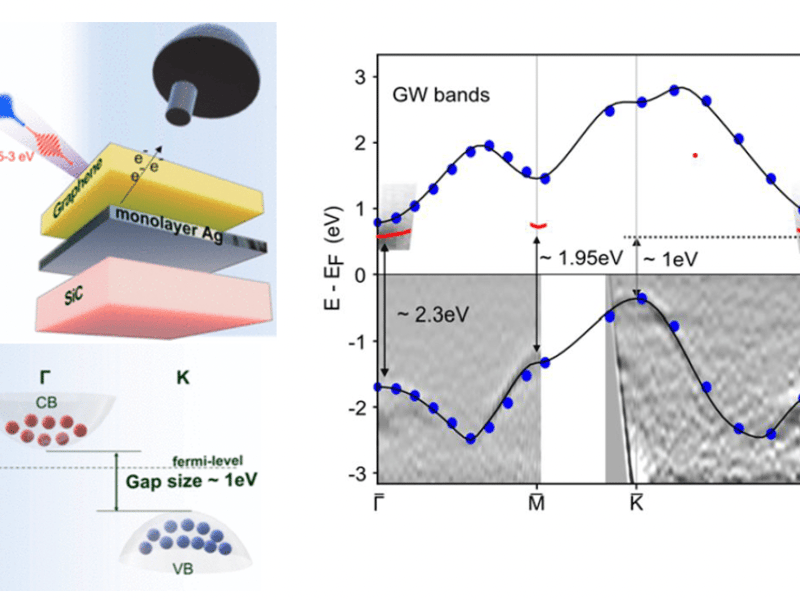

Confined Monolayer Ag as a Large Gap 2D Semiconductor

Shih, MacDonald, Li (UT MRSEC); Crespi, Robinson (Penn State MRSEC)

Showing 141 to 150 of 1394