General Overview: The Wisconsin MRSEC is investigating innovative methods to incorporate a greatly expanded diversity of atom types into semiconductors, thus yielding materials with a new range of electronic properties. Semiconductors are the foundation of modern electronic and photonic devices, and are widely used in technologies such as solar cells, LEDs, and microprocessors. Incorporating new atom types into semiconductors will expand the range of semiconductor materials and potentially lead to a new generation of devices. The Wisconsin MRSEC has focused on developing methods that permit incorporation of atomic bismuth (Bi) into a widely used semiconductor comprised of gallium arsenide (GaAs). Incorporating Bi into GaAs is challenging due to the significant size differences between the atoms, which results in Bi migrating to the surface rather than forming a mixture. By carefully controlling the rate at which Bi atoms were added to GaAs and using special imaging tools to characterize the level of Bi incorporation, the Wisconsin MRSEC unexpectedly discovered a growth process that leads to incorporation of high concentrations of Bi. This finding promises to make the process of growing  complex semiconductor materials more efficient such that these materials could eventually be synthesized in the quantities needed for more efficient commercial semiconductor-based devices from solar cells to cell phones.

complex semiconductor materials more efficient such that these materials could eventually be synthesized in the quantities needed for more efficient commercial semiconductor-based devices from solar cells to cell phones.

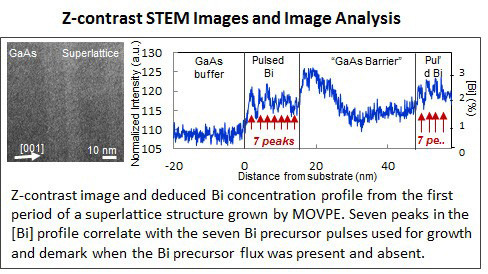

Technical Description: Wisconsin MRSEC researchers grew metastable GaAs1-yBiy materials using metalorganic vapor phase epitaxy (MOVPE), a process utilizing surface chemical reactions to enable controlled growth of complex multilayer crystals. The Bi concentration profile that developed during growth of the GaAs1-yBiy materials was analyzed using high-angle annular-dark-field (“Z-contrast”) imaging in an aberration corrected STEM. Surprisingly, these studies show that surface adsorbed Bi atoms incorporate into the growing alloy more readily when the Bi precursor is absent from the growth environment. Consequently, the most Bi-rich material in the superstructure grew when GaAs barrier growth was intended. Pulsing of the Bi source has proven effective in enhancing Bi incorporation during growth. Recognizing when Bi is incorporated is essential when designing superstructures and their growth. Wisconsin MRSEC researchers also grew GaAs1-yBiy films using molecular beam epitaxy (MBE) which is a physical rather than a chemical deposition process. These results could lead to increased efficiency in Bi incorporation resulting in growth methods that can be used to in commercial production of GaAs1-yBiy containing devices.