Filament Surface Heating.

Filament Surface Heating.

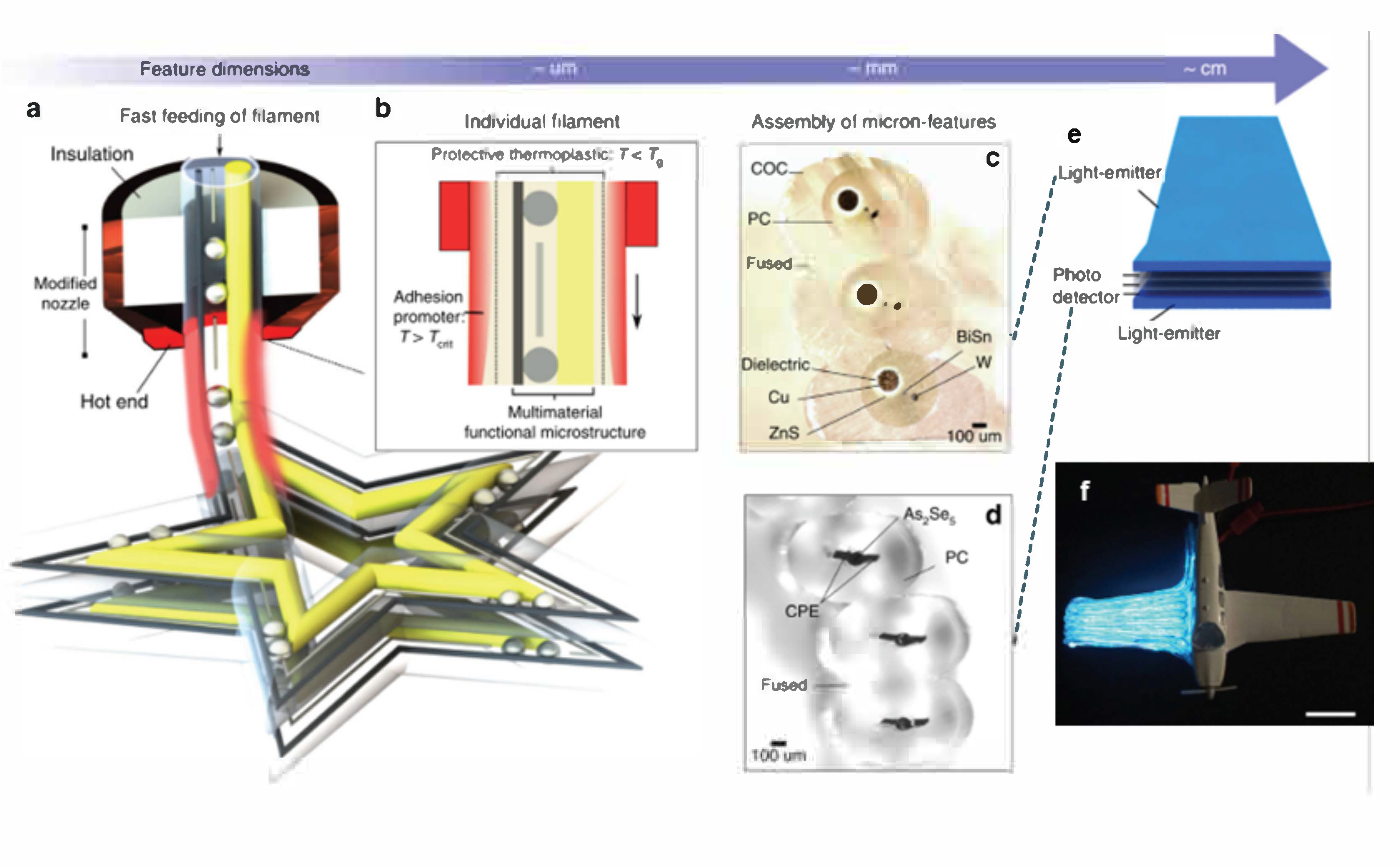

Functional fibers fabricated by the thermal drawing process can be used as feedstock for 3D printing. By applying an outer cladding with a lower Tg compared to that of the fiber core, the surface of the fiber can be heated to enable fused filament fabrication while the inner core is not affected (see Figure a-c).

Capillary Breakup.

The light-emitting fiber consists of BiSn micropheres, electroluminescent ZnS, conductive W, and a COC cladding. The BiSn microspheres are formed using laser-induced capillary breakup. The microspheres are larger than the cladding (shown in Figure b), so they connect the W and ZnS. When an alternating voltage is applied, the ZnS layer emits light.

Localized Detection.

The light-emitting fibers are a step toward fabric or 3D-printed displays. Furthermore, the light-emitting and photodetecting filaments can be used together in a structure for the purpose of detecting structural defects (see Figure e, f). The presence of a structural defect reduces the magnitude of the photocurrent measured from an external multimeter. Although 3D printing is demonstrated using optoelectronics, the method of filament surface heating for 3D printing can be applied to multimaterial filaments of a variety of functionalities.