We

utilized microfluidic

methods to investigate

the role of geometric structures, e.g. thin spherical block copolymer shells,

in the microphase

separation

in block copolymer thin films. The shells are comprised of the triblock

copolymer styrene-isoprene-styrene

(SIS).

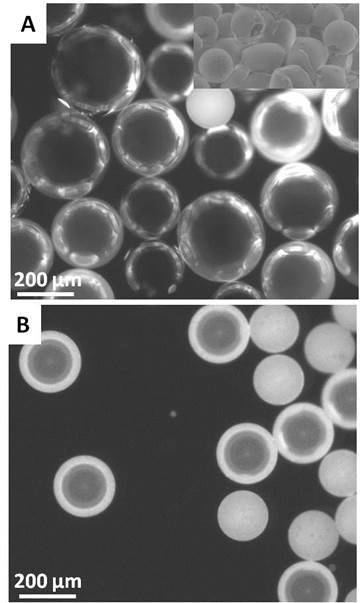

For

air-in-oil-in-water emulsions, microfluidic devices with two consecutive

flow-focusing junctions were used to generate air bubble-containing droplets of

a solution of the SIS triblock

copolymer in toluene in an aqueous solution of poly(vinyl alcohol) (PVA).

The

toluene was allowed to evaporate, leaving thin spherical shells of SIS triblock

copolymer suspended in PVA solution (Fig. 1). The use

of microfluidic methods to generate such particles facilitates the

straightforward modification of the inner phase composition to study the effect

of different chemistries of the core on block copolymer microphase

separation, as well as the effect on the mechanical stability of the shell.

Figure

1

(A)

Fluorescence image of an air-in-oil-in-water emulsion.

The inner phase

is air, the middle phase is composed of styrene-isoprene-styrene triblock

copolymer, and

the outer phase is water. (B)

Fluorescence image of a water-in-oil-in-water double emulsion.