From drug delivery to catalysis

to optoelectronics, the need for efficient fabrication pathways

for particles

over a

wide range of sizes, from a variety of materials, and in many

different structures

is

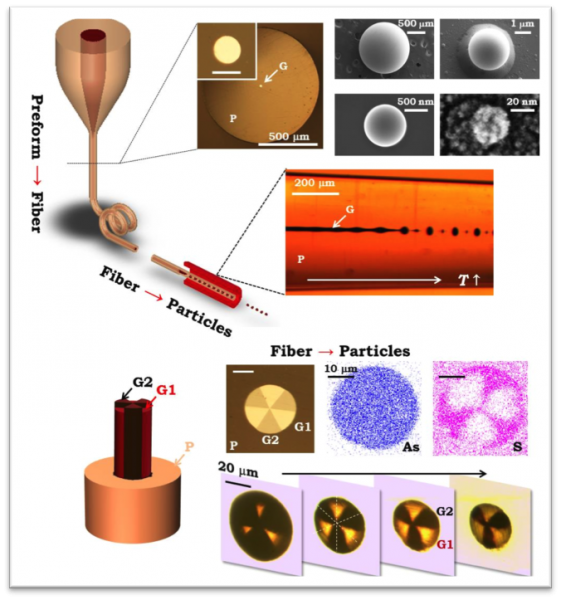

critical to functionality. Researchers in IRG-III have exploited the inherent scalability

of fiber production and an in-fiber Plateau–Rayleigh capillary

instability for the fabrication of uniformly sized,

structured spherical particles spanning an exceptionally wide range

of sizes: from 2 millimeters down to 20

nanometers.

By arranging a

variety of structures and materials in a macroscopic scaled-up

model of the fiber, composite structured spherical particles,

are

produced such as core–shell particles, two-compartment

‘Janus’ particles,

and

multi-sectioned ‘beach ball’ particles (see figure). Moreover,

producing fibers with a high density of cores allows

for an

unprecedented level of parallelization. This new process makes it possible for

the first time to produce nanostructures containing

diverse materials in prescribed complex architectures and

manufactured in

large quantities.

This development has significant implications for photovoltaics,

electronic devices, medicine and health-care, targeted drug delivery, chemical

sensing and catalysis, photonics, and cosmetics.

Top: Instability