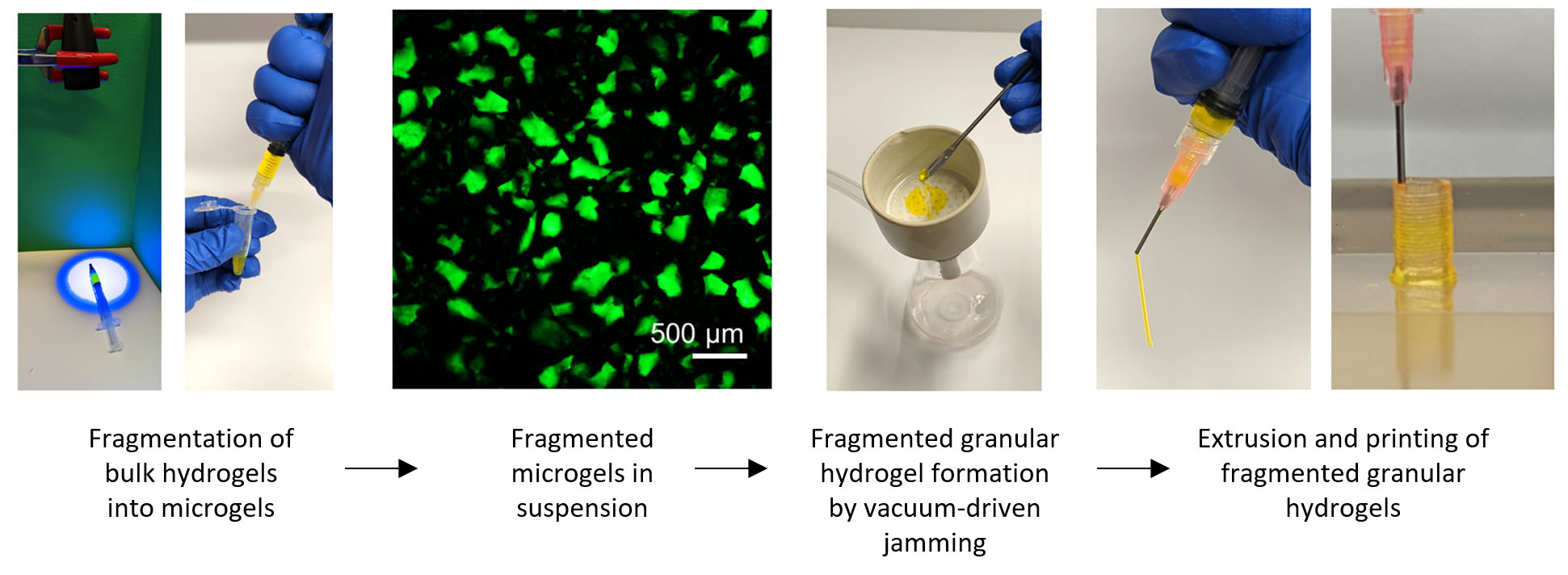

Fabricating Granular Hydrogels for 3D Printing

Granular hydrogels are jammed assemblies of hydrogel microparticles (i.e., “microgels”) widely explored in biomedical applications due to promising features such as shear-thinning to permit injectability and inherent porosity for cellular interactions. One area where this is particularly promising is in 3D printing.

- To share this technology with others, we report a methods article on fabricating particles from photocrosslinked hydrogels, jamming the particles into extrudable solids, and then 3D printing the granular media into desired 3D structures (see figure) [1]. A great advantage to this platform technology is that hydrogel fragmentation was used to make particles, which allows for the processing of essentially any hydrogel into granular and printable formulations.

- Using this technology, the Arratia and Burdick groups collaborated to fabricate granular hydrogels by mixing microparticles with complementary chemical groups that formed dynamic covalent bonds when in contact [2]. These chemical interactions altered the flow behavior of the granular media but still permitted 3D printing. Interestingly, the printed constructs were stable due to these chemical interactions, without any post-crosslinking needed.

[1] V.G. Muir, M.E. Prendergast, J.A. Burdick, Methods to Fragment Bulk Hydrogels and Process into Granular Hydrogels for Biomedical Applications, Journal of Visualized Experiments, 183:e63867, 2022.

https://doi.org/10.3791/63867

[2} V.G. Muir, T.H. Qazi, S. Weintraub, B.O. Torres Maldonado, P.E. Arratia, J.A. Burdick, Sticking Together: Injectable Granular Hydrogels with Increased Functionality via Dynamic Covalent Inter-particle Crosslinking, Small, 18:2201115, 2022.

https://doi.org/10.1002/smll.202201115