Crystalline silicon is a critically important electronic material in all consumer electronic products. The ability to create fibers from this material would open up exciting vistas for a new generation of fiber-based electronic and optical devices. Traditional fiber-optic drawing involves a thermally mediated geometric scaling where both the fiber materials and their relative positions are identical to those found in the fiber preform. To date, all thermally drawn fibers are limited to the preform composition and geometry.

MIT MRSEC researchers have demonstrated (see figure) that it is possible to fabricate a meter-long crystalline silicon-core, silica-cladded fiber from a preform that does not contain any elemental silicon but rather aluminum and silica (glass). The ability to produce crystalline silicon core fibers out of inexpensive aluminum and glass paves the way for a simple and scalable method of incorporating silicon-based electronics and and photonics into fibers.

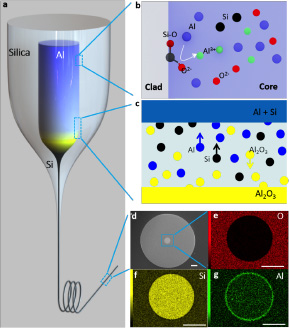

Figures: a, schematic of aluminum-core-quartz-cladding preform drawn into Silicon-core fiber. b, the chemical reaction at the core-cladding interface. Al atoms (blue) break Si-O bonds, reduce Si (black), release O2- ions (red), and change to Al3+ ions (green). All the products of ions and atoms dissolve in the Al melt and diffuse into the core. c, the Si atoms (black), because of their miscibility, diffuse and remain in the Al melt (blue), while ions of O and Al form Al2O3 molecules (yellow) and precipitate out at the bottom. d-g, the SEM and EDX analysis on cross section of the Si-core fiber. Scale bar: 100 µm in d, 50 µm in e-g.