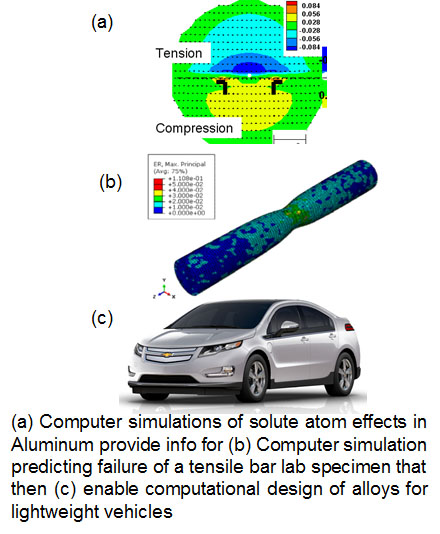

Replacing steel with lightweight Aluminum alloys could significantly improve fuel economy of vehicles. Existing lightweight alloys are difficult to use, because they have poor ductility, and tend to tear while they are stamped to form a complex part. Adding small quantities of additional allying elements to lightweight alloys could improve their ductility. But at present the only way to identify the correct elements is to make, and test, many possible combinations - an impossible task.

A recent breakthrough by researchers at Brown and General Motors means

that new 'virtual' alloys can now be designed and tested on the

computer. This will dramatically accelerate alloy development.

Computer simulations start by modeling the effects of alloying on atomic

bonding in a material - by using quantum mechanics to simulate

indivudal atoms. Information from atomic scale computations then

provide parameters for simulations of an entire vehicle part.