One of the biggest challenges in developing materials that can be used for cartilage replacement and for cartilage tissue scaffolds is optimizing the material properties to compare to native cartilage tissue; a critical task, as the implanted specimens must withstand substantial dynamically-varying loads. The artificial tissue is required to be elastic, tough and resilient.

One of the biggest challenges in developing materials that can be used for cartilage replacement and for cartilage tissue scaffolds is optimizing the material properties to compare to native cartilage tissue; a critical task, as the implanted specimens must withstand substantial dynamically-varying loads. The artificial tissue is required to be elastic, tough and resilient.

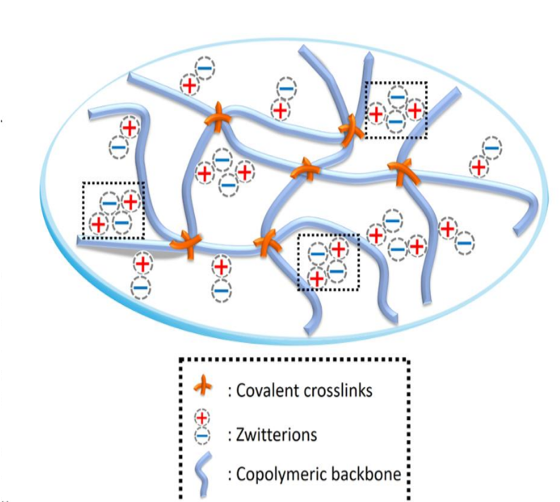

Cornell researchers employ advanced 3D printing technologies, along with bio-inspired design principles and multiscale predictive modeling to optimize the chemo-mechanical properties of bioprinted artificial cartilage. Optimal materials exploit the natural similarities of cartilage and zwitterionic/collagen double network hydrogels.