One of the primary ways that materials fail in operation is by the formation and propagation of cracks during loading, often leading to sudden, catastrophic events.

One of the primary ways that materials fail in operation is by the formation and propagation of cracks during loading, often leading to sudden, catastrophic events.

The ability of a material to withstand fracture is described as its toughness. Over the years, researchers have developed a variety of way to enhance material toughness, thereby improving the ability of materials to withstand applied loads, but often at the cost of reducing overall strength.

In this study, Penn MRSEC researcher Kevin Turner, and Michal Budzic of Aarhuas University in Denmark have shown that it is possible to control how a material can resist fracture by leveraging architecture, rather than by modifying material composition or microstructure as has been conventionally done.

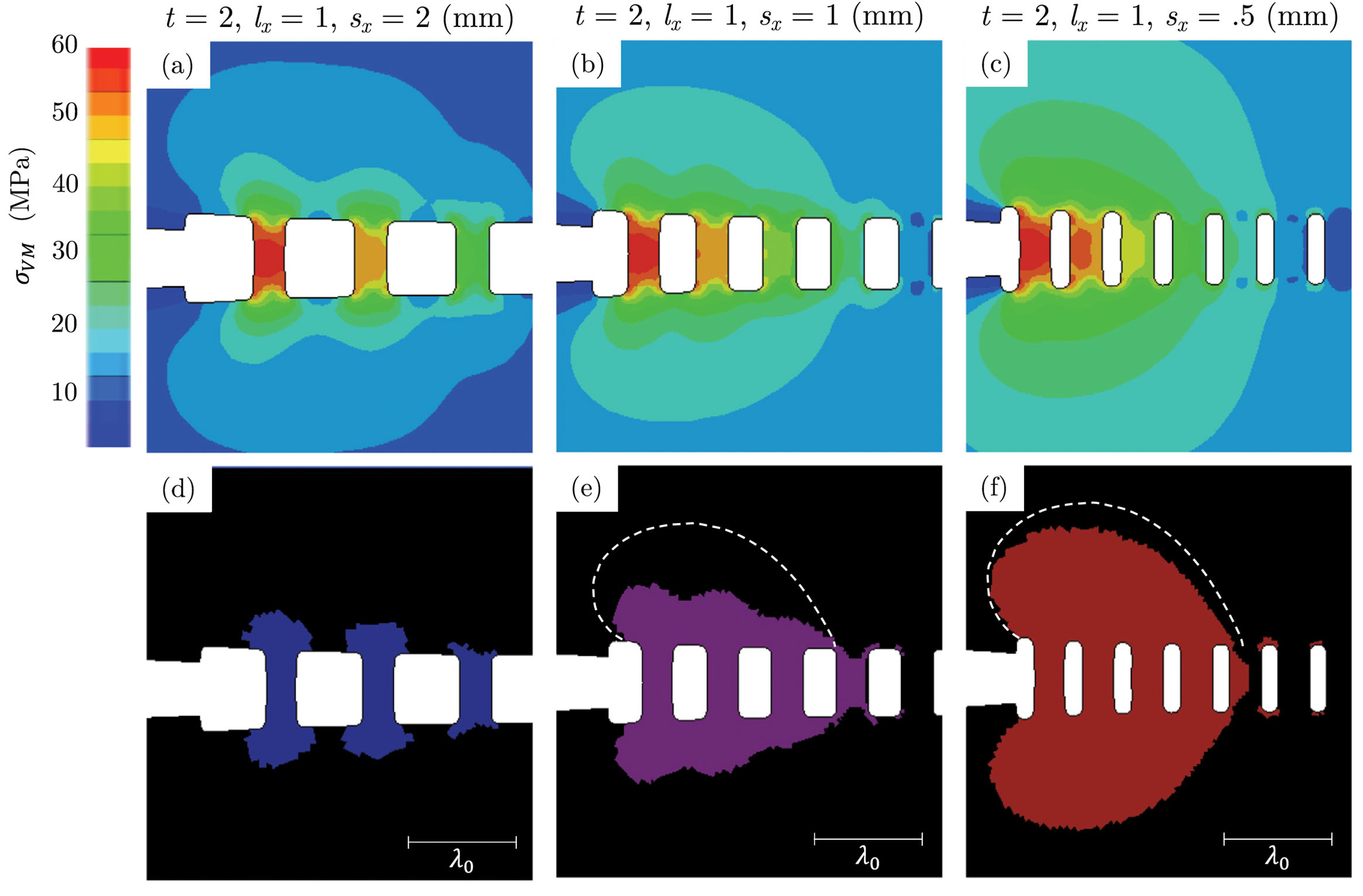

They developed analytical models to predict the plastic zone geometry and resulting toughness enhancement for an elastic-plastic material containing a periodic array of pillars along the crack path, and optimized the size and placement of these pillars to achieve a remarkable 3.5 increase in fracture toughness without significant loss in strength.

Image Caption: Simulations showing how the height (t), length (lx) and spacing (sx) alter the stress (σVM) at a crack tip and thereby prevent crack propagation and increase toughness

Fulco, S., Budzik, M. K. and Turner, K. T., Enhancing toughness through geometric control of the process zone. JMPS,184, 14 (2024) 10.1016/j.jmps.2024.105548 https://doi.org/10.1016/j.jmps.2024.105548