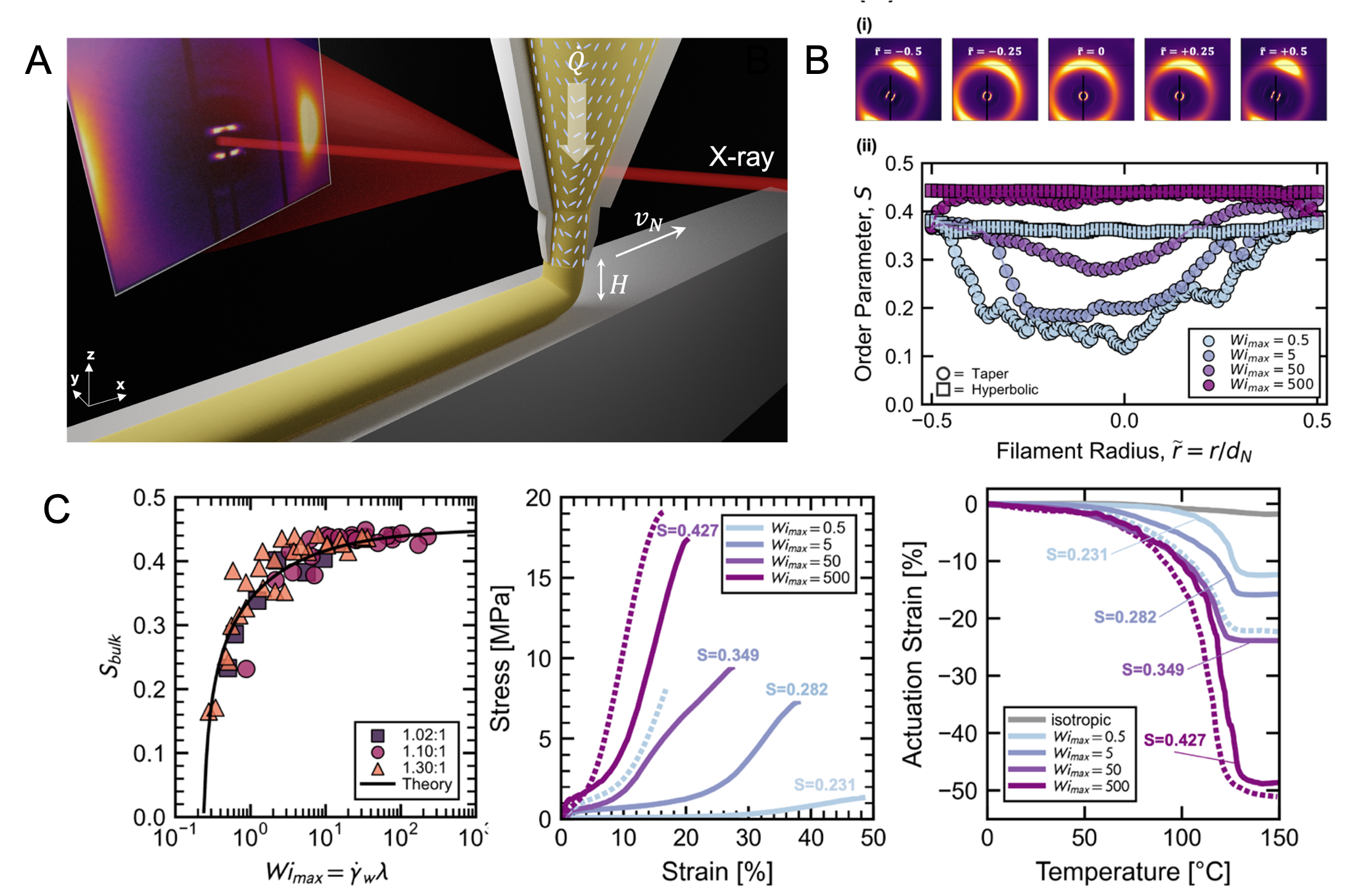

Aligned liquid crystal elastomers (LCEs) are soft materials that exhibit reversible actuation akin to human muscles when thermally cycled above their nematic-to-isotropic transition temperature. Lewis and collaborators studied the effects of LCE ink composition, nozzle geometry, and printing parameters on director alignment. By combining rheological measurements, in-operando microbeam X-ray scattering, and simulation, we show that the dimensionless Weissenberg (Wi) number, which characterizes ink flow through tapered and hyperbolic nozzles, directly correlates with director alignment in printed LCE filaments. By altering the value of Wi on-the-fly during printing, one can fabricate monolithic LCE actuators with spatially programmable alignment, stiffness, and actuation strains.

Spatially programmed alignment and actuation in printed liquid crystal elastomers

Harvard Materials Research Center

The Harvard MRSEC focuses on unraveling complex phenomena in soft materials with the goal of translating these advances to benefit society.