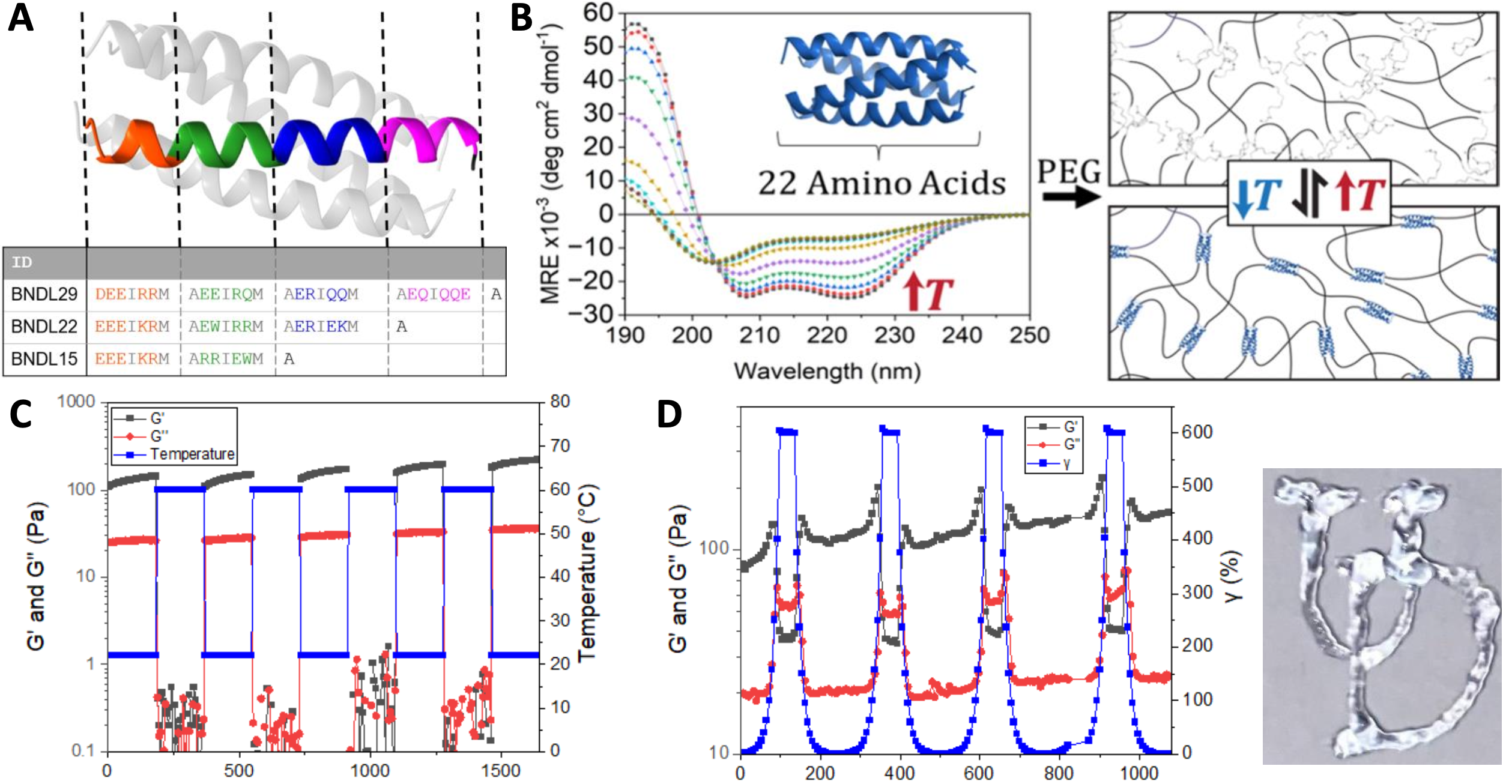

Computationally designed tetrameric coiled coils, ranging from 8-29 amino acids, revealed a minimum of three heptads (21 amino acids) is necessary for stable coiled coil formation, establishing a minimum sequence for the creation of building blocks to construct nanostructured material.

The designed 22-residue sequence (BNDL22) formed coiled-coil building blocks with a melting temperature of 58°C and stability across various pH values (4-11) and types and concentrations of salt, all of which are useful for applications and provide handles for designing responsiveness into a range of materials.

BNDL22 was incorporated within hydrogels as a thermoresponsive and shear-thinning cross-linker for reversibly cycling properties and enabling material processing for 3D printing and injectable applications.

Overall, through computational and experimental interdisciplinary collaboration, design rules for dimeric coiled coils were established, with a balance between design simplicity and dynamic functionality. These building blocks and the resulting responsive nanostructured materials are relevant for future use in the design and construction of molecular and nano machines.

Impact of Peptide Length and Solution Conditions on Tetrameric Coiled Coil Formation

Center for Hybrid, Active, and Responsive Materials

UD CHARM advances foundational understanding of new materials driven by theoretical and computational predictions paired with cutting-edge experiments to enable the integration of unconventional, ultra-small, building blocks.