A class of synthetic soft materials called liquid crystal elastomers (LCEs) can change shape in response to heat, similar to how muscles contract and relax in response to signals from the nervous system. 3D printing these materials opens new avenues to applications, ranging from soft robots and prosthetics to compression textiles.

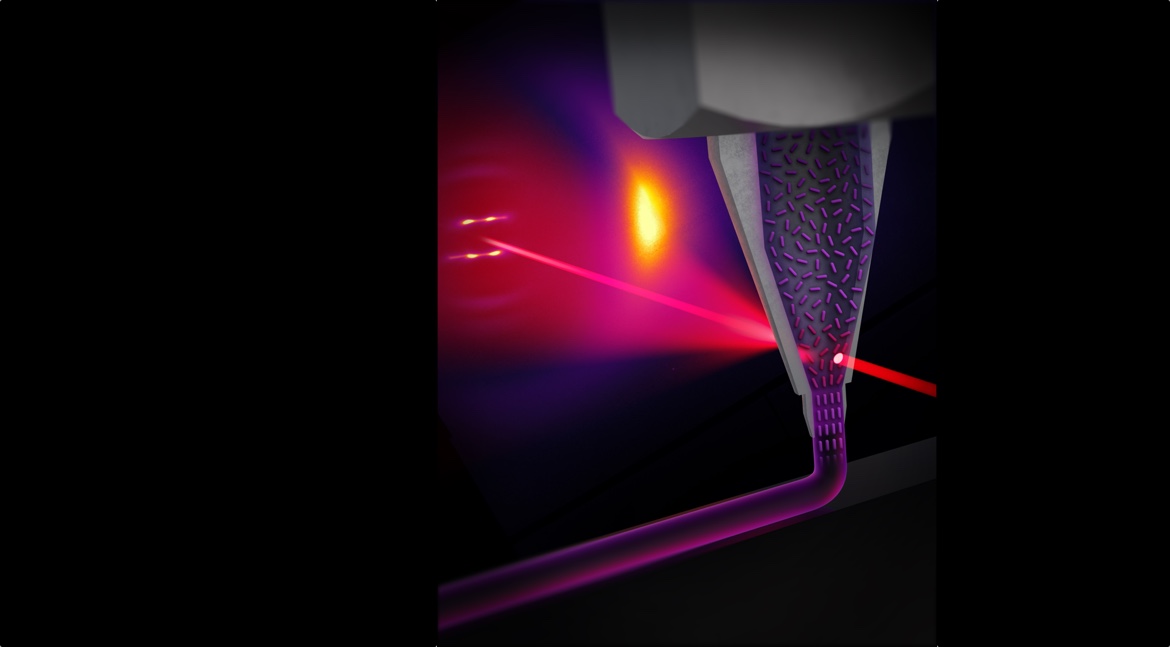

Controlling the material's properties requires squeezing elastomer-forming ink through the nozzle of a 3D printer, which induces changes to the ink's internal structure and aligns rigid building blocks known as mesogens at the molecular scale. However, achieving specific, targeted alignment, and resulting properties, in these shape-morphing materials has required extensive trial and error to fully optimize printing conditions. Until now.

In a new study, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), Princeton University, Lawrence Livermore National Laboratory, and Brookhaven National Laboratory worked together to write a playbook for printing liquid crystal elastomers with predictable, controllable alignment, and hence properties, every time. By using an X-ray characterization method during the printing process that enables quantification of mesogen alignment at the microscale, the researchers have established a fundamental framework to guide their rapid design and fabrication across multiple scales.